お知らせ・お役立ち便覧 NEWS

洗剤・溶解・剥離

2024.11.20

超音波洗浄機について

金

合わせて読みたい!

超音波洗浄機とは

超音波洗浄機とは、超音波を発生させ洗浄する洗浄機のことです。

もともと工業的には広く使われていましたが、現在ではメガネの洗浄機や、貴金属・腕時計の金具ベルトの洗浄用に個人が容易に購入できるほどメジャーなものとなって、超音波のおかげで従来の洗浄方法では落とせなかった汚れも洗浄できるようになりました。

超音波洗浄は超音波の物理的作用と、洗浄液の化学的作用を組み合わせることで洗浄効果を高めています。

洗浄液の化学的な効果だけでは落ちなかったものが、キャビテーションや振動加速度による物理的作用で汚れを剥離、分散、乳化し、微細な汚れなども洗浄できるようになったのです。

また、超音波洗浄には、洗浄品質の均一化や、洗浄時間の短縮化も期待できます。

なぜ超音波で洗浄できるの?

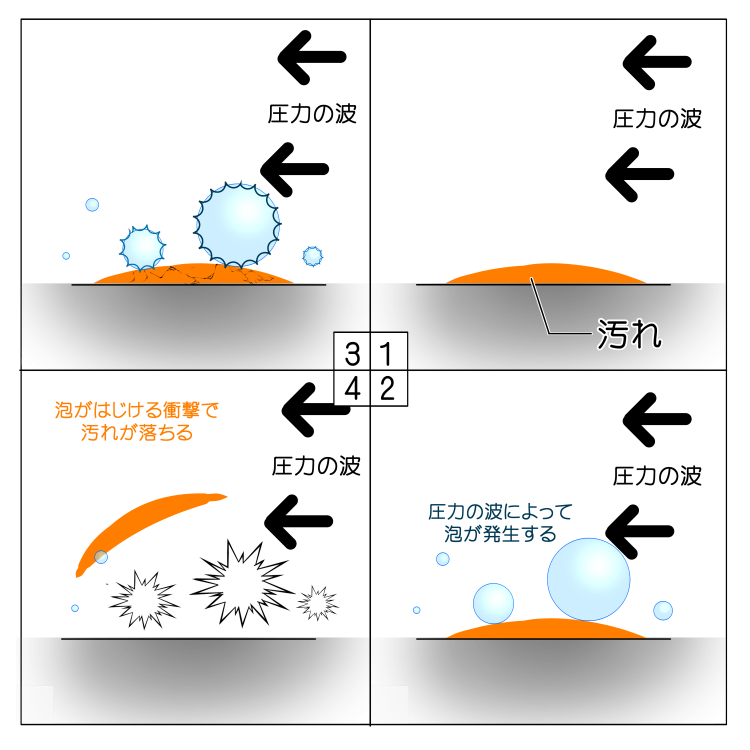

①超音波キャビテーション

液体の中で起きた流れによって圧力差が発生し、泡が短時間の間に発生・消滅を繰り返す物理現象のことをキャビテーションと言います。

別名「空洞現象」とも言います。

液体中に強力な超音波を照射すると、真空に近い無数の微小空洞(=キャビテーション)が発生します。

そのキャビテーションが潰される瞬間に強力な衝撃波が生じ、ワークから汚れを直接破壊、液中に分散させ洗浄ができる仕組みです。

この衝撃波は実はかなり強力で、条件によっては水中に入れたアルミ箔にキャビテーションの衝撃波を与えると数十秒で穴が開いてしまうほどなのです。

キャビテーションによる洗浄は油汚れに効果的であると言われ、下の図のように汚れをおとしていきます。

キャビテーションの発生具合は液の深さや液の種類、超音波の周波数によって変化し、洗浄対象に合わせて調整します。

周波数が小さいほどキャビテーションが大きくなり、潰れるときの衝撃波が大きくなります。

周波数が大きいほど、キャビテーションが小さく、衝撃波も小さいので精密部品などの洗浄に用いられます。

②超音波振動

液体に超音波を照射すると、液体分子が振動します。

この振動の加速度は、超音波をかけずに静置している状態よりも、

28kHzの場合は1000倍

950kHzの場合は100000倍もあります。

この驚異的な振動のスピードで汚れをワーク表面から引き剥がします。

950kHzの超音波は波が細かすぎてキャビテーションが発生しないので、油汚れの洗浄はできませんが、サブミクロンの汚れを洗浄することができます。

周波数について

950kHzの周波数では油汚れの洗浄はできないと書きましたが、周波数によって落とせる汚れの得意分野が違います。

適切な周波数を選択することで、洗浄効果が最大限に発揮出来るようになるので、事前のチェックが必要です。

ダメージが大きい順に周波数と汚れの相性を見ていきましょう。

周波数:28kHz

洗浄エネルギーが強く、油落としや目に見える大きなゴミの洗浄に最適です。金属部品や樹脂パーツを洗うことができます。

周波数:40kHz

28kHzよりもダメージは少ないので、精密部品やガラスなどを洗うのに最適です。具体的には眼鏡やアクセサリーを洗浄する場面で活躍します。埃などを落とすのに適しています。

周波数:100kHz

最近注目を集めている周波数です。40kHzでもダメージが発生してしまう場合に使用します。ハードディスクやCSP基盤など、電子関係の精密部品の洗浄に向いています。

周波数:160kHz

ワークへのダメージが少なく、微細な汚れの除去が出来ます。化合物ウェーハやハードディスクなどの洗浄に最適です。

周波数:400kHz

0.2~5μmの汚れの洗浄が可能です。

周波数:1MHz

目に見えないような汚れの除去に使われます。ワークへのダメージも少なく、ウェーハ洗浄で注目を集めています。

周波数:3MHz

0.2μmの洗浄に最適です。加速度としては1MHzよりも強く、それでいて1MHzよりも微細な汚れを除去できます。

超音波洗浄機のタイプ

超音波洗浄機は主に、

超音波を発生する超音波振動子と、超音波振動子を動かすための超音波発振器、そして液体を入れる槽からできています。

既存の槽に、振動子と発振器をつけるタイプや、槽と振動子・発振器の3つが一緒になったタイプがあります。

槽が別のタイプでは、特殊な洗浄物で槽の形が独特でも対応できたり、移設や移動が比較的簡単なことが長所です。

ワンボディーにまとまったタイプは狭い所にも置きやすかったり、比較的コンパクトな点が特徴です。

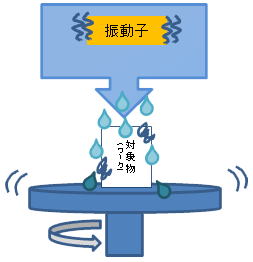

また、浸け置くタイプが多い中、超音波を水流に載せて洗浄するタイプもあります。(下図参照)

また、超音波洗浄機には超音波をかけるだけでなく、他の機能もついているものがあります。

例えば、液温を上げるヒーターが付いているものや、減圧機能が付いているものなど、超音波と組み合わせることでより洗浄効果を高めることができる機能です。

他にも、

様々な洗浄液が使えるよう、防爆仕様がついていたり、

色々な汚れに対応できるよう周波数を変えることができる機能がついているなど、

便利な機能が沢山あるので、導入を考えられている方はしっかりチェックしましょう。

超音波洗浄機の選び方

ここまでで、超音波洗浄機と一言にしても様々な種類があることがお分かり頂けたと思います。

周波数や形だけでなく洗浄液も、洗浄機との相性を考慮しなければなりません。

超音波の物理的作用と、洗浄液の化学的作用を組み合わせることで、洗浄効果を最大限に引き延ばすことが重要です。

①洗浄の目的を明確にする

洗浄機を選ぶ前に、今一度何を洗浄したいか明確にします。

例)脱脂、研磨粉・切粉の洗浄、パーティクルの除去 など・・・

②ワークの種類を把握する

被洗浄物がどのようなものかしっかり把握しておきます。

例)ワークのサイズはどれくらいか、どういった成分でできているか など・・・

状況をしっかりと認識した上で洗浄機を見ていきます。その時重要になってくるのは下記です。

③洗浄液を選ぶ

洗浄液は、それはもう大量の種類があります。

間違った洗浄液を選択してしまうと、まったく洗浄できないこともありますので、この選択は非常に重要です。

水系・溶剤系に加え、最近では「準水系」の洗浄剤が超音波洗浄において特に注目されています。

もともと超音波洗浄機では、フロンや塩素系の溶剤を使って洗浄されることが多かったのですが、健康や環境への悪影響から代替化の検討が進んでいるのです。

④周波数を選ぶ

既にご紹介の通り、周波数によって得られる効果が違います。

そのため、目的に応じた周波数を選択しなければなりません。

また、卓上タイプの超音波洗浄機は超音波の出力点が少なく、同じ周波数でも洗浄能力に差が出てしまうので注意してください。

⑤洗浄位置を考慮する

超音波洗浄機では、その圧力がどの部分に一番よく届くのかを考える必要があります。

②でサイズを把握されたと思いますが、仮に洗浄機にワークが入ったとしても、大きすぎるワークでは洗浄ムラが生じる場合が多く、その状態では洗浄効果を100%引き出せません。

一般的には、揺らすなどしてムラをなくすことも可能です。

⑥インサートトレイを選ぶ

直接洗浄槽にワークを置くと、振動子にワークが触れてしまうなどして、正常な超音波が出なくなり、洗浄不良や故障の原因になってしまいます。

その対策として、インサートトレイと呼ばれる容器や、洗浄籠を用いるのが一般的です。

しかし、そのトレイのタイプや、洗浄籠の網の細かさなどによっては超音波が大きく減衰してしまい、洗浄効果が落ちてしまう場合がありますので、使用の際は適切なものを選びます。

⑦液温の設定

一般的に液体の温度が上がると、液中に気泡が発生してしまい超音波が弱くなってしまいます。

しかし、洗浄液単体で見た場合、液温が上がるほど洗浄力がよくなるのが通例です。(但し加温限界温度以上上げてはいけません!)

そのため、超音波と洗浄液のそれぞれの効果が最大限に出るポイントを探さなくてはなりませんが、これは洗浄液によって異なります。

例えば水の場合は、50~60℃が最適だと言われています。

考慮しなくてはならない点が沢山あって大変だと思いますが、合った洗浄機・洗浄液が見つかれば作業性も大きく変わります。

洗浄液のご相談も受け付けておりますので、お気軽にご連絡下さい!

関連製品

以下の超音波洗浄機向け洗浄剤を三協化学では取り扱っております。

超音波洗浄に関する質問

※2024年11月20日更新

以前、ページのコメントに寄せられた疑問・質問とその回答をご紹介します。

(※一部編集・抜粋しております)

質問No.01~10

※「▼」をクリックすると質問が表示されます。

ニクロム線のコイリングに機械油を使用⇒油脂洗浄に超音波効果はどれ程でしょうか?

ニクロム線のコイリングの脱脂洗浄でございましたら、超音波洗浄は効果があり、洗浄可能でございます。ただ、その際の洗浄液の選定にはご注意いただきたいと思います。

ドン・キホーテでメガネ用の超音波洗浄機見かけましたが、ああいうのって意味あるんですか?

端的に言わせていただくと、意味はあります!

眼鏡には沢山の隙間が(レンズとフレームの間や、フレームの飾りなど)ありますが、その隙間に入ってしまった汚れなどを超音波洗浄機では落とすことができます。

威力が弱いのではないか、もっと強いものがいいのではないかと思われるかもしれませんが、眼鏡は精密機器なので、あまり強い超音波で洗われてしまうとレンズに傷が入ってしまったり、精度に支障が出る可能性があります。

家庭用ファンヒーター(機器)の掃除を大量に扱っています。

構造が複雑で、機械の内部にも埃が付着しており、清掃に手間が掛かります。例えば洗浄液に機器をドブ漬けして、超音波洗浄できないでしょうか。

又、ドブ漬けの場合電子部品に影響がありますか?その場合、早急な乾燥で対応できないでしょうか。

超音波は物理的な力になりますので、電子部品に影響を与える可能性がございます。その点は超音波洗浄機にもよりますので、超音波洗浄機メーカー様にご確認ください。

また、洗浄液に関しては、洗浄されたいパーツがどの部分にあたるのかにもよります。

コンデンサに電圧がかかっているとショートしてしまうものもございますので、炭化水素系洗浄剤などの極性のないものがおすすめですが、一方で炭化水素系ですと水溶性の汚れには不向きな面もございます。

現在リールのメンテナンスをしようと超音波洗浄機を買いました。そこで、無水エタノールで洗浄しようと思うのですが洗浄効果ってどれほどのものなのでしょうか?

リールの汚れの性質にもよりますので、試してみないと分かりません。

ですが無水エタノールは引火点が低く、その液体を防爆仕様でない電子機器にかけるということは、火花が散ったりして火災につながることが多く弊社としてはあまりお勧めできません。

チタン合金を超音波洗浄で脱脂をしたいのですが。効果的な洗浄液とかわかりますでしょうか?

洗浄剤は数多ございますので、マフティー様がどのような条件の洗浄剤をご希望するかによっても変わってきます。

また、使用されている超音波洗浄機は防爆仕様のものでしょうか。防爆仕様になっていなければ、非危険物や引火点40℃以上の洗浄剤をご使用ください。

SUS304の表面に付着した異物を除去したいのですが、超音波洗浄て可能ですか?出力は50~70mv程度です。

超音波洗浄機によっても、相性が異なる場合がございますのでお手持ちの超音波洗浄機のメーカー様へお問い合わせください。

鋳物製品で、成形後、中子を取り除くのですが表面に砂が残るので超音波洗浄したいのですが、シミュレーションツールなどはあるのでしょうか。

洗浄に最適な超音波照射位置を特定したいのでコンピュータシミュレーションしてくれと言われました。どうしたらよいですか?シミュレーションツールなのあるのでしょうか?

流体解析や構造解析ならよくやっているのですが、超音波はどんな物理法則をどのように解くのかさっぱりです。(キャビテーションがないなら音響解析ツールでもよいような気がします。)

超音波のシュミレーションに関しては、超音波洗浄メーカー様にお伺い頂くことをお勧め致します。申し訳ありません。

金属巻き線フィルターのスケール除去に使用したいのですが、適切な周波数や被洗浄物との距離など、気を付ければよいことはありますか?

弊社でご紹介をしておりますのが、一般的な周波数についてでございますので、具体的な事例や、実際にどのように使用したらよいかは、機材によってもまちまちのため、洗浄機メーカー様へお問い合わせいただくのが確実です。

最近、40Hz超音波洗浄器を流しに設置して食洗機として使える商品が日本で予約販売開始されました。Brand Design Plusという会社です。

購入を検討していますが、中国製なので、他の商品の様に40Hzの超音波がちゃんと出ていない可能性はありますが、40Hzの超音波が出たとして、従来の食洗機の様に油汚れや様々な食器汚れを洗う事は可能ですか?

実際に弊社でそちらの製品を使用して実験していないので、なんとも申し上げることができません。申し訳ありません。

もしメーカー様が中国語のみの対応であれば、販売店様へお問い合わせ頂くのがよろしいかと思います。

キッチンの油汚れ(換気扇油・コンロのこげ))などは洗浄液、つけ置き、温度をふまえ超音波でおちるものでしょうか?

洗浄液がどのような成分によるものなのか判断ができないため、弊社では分かり兼ねます。ご使用になられる洗浄液のメーカー様へお問い合わせ願います。

カテゴリーから探す

キーワードから探す